高精密注塑件定制生产厂家提供产品设计优化/模具制造/注塑量产一站式服务

始于2008年,以客户为本,立足技术,秉承服务驱动成长的理念,专注高精密模具的定制加工,提供模具设计、模具制造、注塑加工、表面处理一站式OEM/ODM定制化服务。15年来,美域同润(Mastars)历经市场验证,一直坚持技术创新,为众多企业提供更高精的精密模具。

- 15年

行业经验

- 15000㎡

生产基地

- 100套

模具月产量

- 134台

生产设备

- 20+项

技术专利

15年的创新理念,伴随着美域同润一直在稳定成长,我们一直秉承根据客户的需求构建新产品的概念。以项目组为单元,灵活的跨职能团队执行新产品开发工作。采用IPD产品开发模式,协同作战,以客户需求为中心,将客户的需求和发展以及市场的激烈竞争放在首位,将技术和客户感知融入PDI执行团队

公司工程设计团队超35人,其中不乏十年以上经验的老牌设计师,以及深圳市宝安区高层次人才。美域同润获得各项国家级专利20多项,经过14年的沉淀,美域同润在同行业中具备明显的技术优势

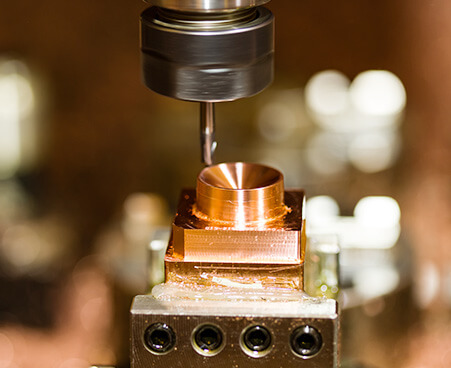

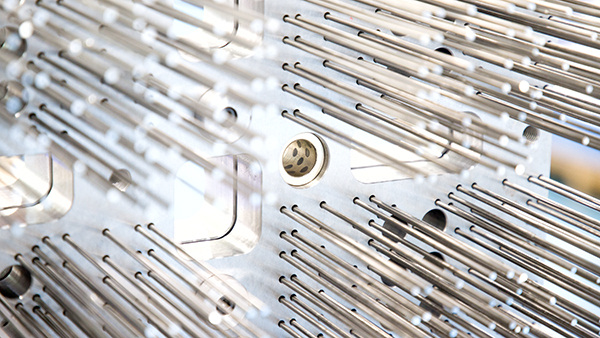

公司拥有德国HERMLE C22、C42、C62 5轴加工中心5台,AGIE火花机、Sodick火花机、Okuma、FANUC等精密模具加工设备,共83台,恒温恒湿生产车间。加工精度可达到0.002mm。T1合格率超90%

美域同润利用业界领先的检测设备和技术,从手板制造开始,一直到量产交付,把控生产过程中的每一个环节,以使每一个生产环节及时合格达标,整个生产流程可以顺畅地进行,总体上这样既保障了产品的高合格率,又让生产周期缩短,大大降低了时间成本。生产品质如何,用数据来说话,数据就是真理!

需求分析定义、挖掘、量化客户要求是需求分析的核心,重要的输入包括产品2D、3D图,产品的使用场景,测量测试要求等,但这些又远远不够,只是冰山露在水面上很小的一部分,我们运用IPD的产品开发理念,多部门从不同维度识别出水面以下更多的隐藏的需求和制约因素。

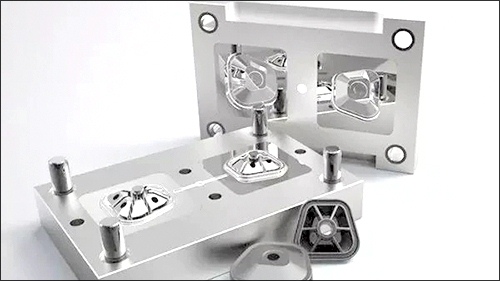

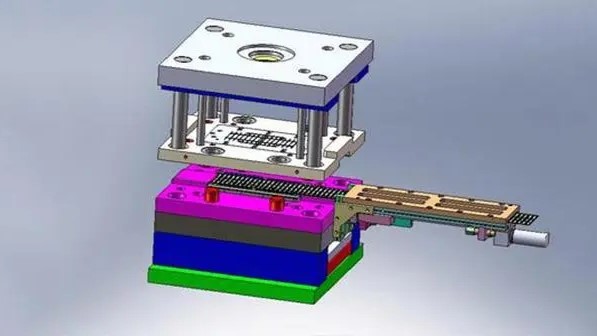

模具设计专项设计师根据客户需求,优化模具结构,对设计工序进行严格规定,24h出模具优化方案,48h出模具3D图

模具开发15年精密模具行业深耕,涉及医疗、汽车、电子、食品、化妆品等领域,20+年经验的行业设计团队,优良的高精CNC、EDM加工设备

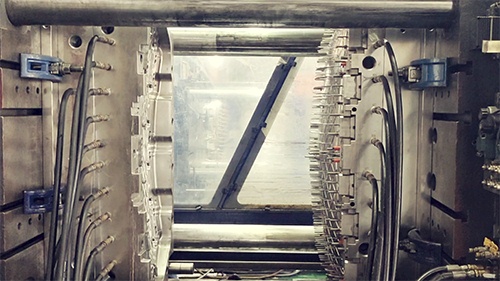

注塑生产拥有恒温恒湿无尘注塑加工车间,20T-400T住友、力劲自动机械手注塑机,确保高精度和高效率

表面处理抛光、喷油、喷粉、喷砂、阳极氧化、电镀等表面处理工艺,满足客户喷油丝印等个性化定制需求

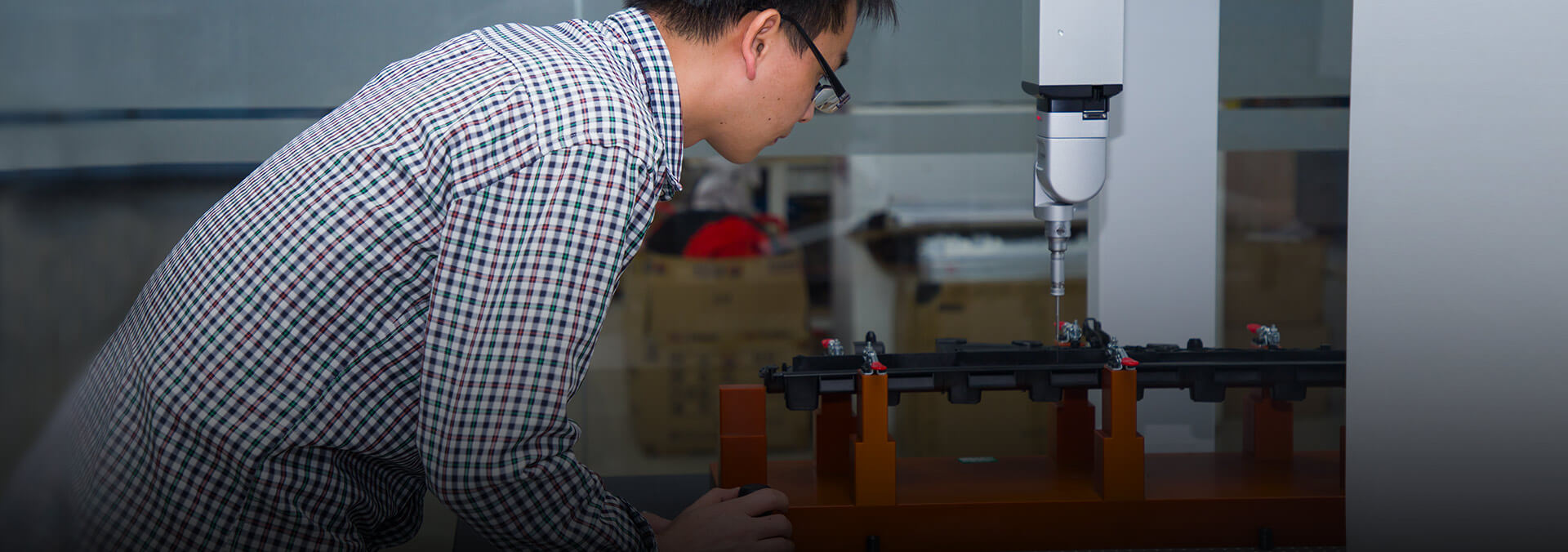

检测组装设立恒温车间,具备三维扫描仪、三次元测量仪、2.5次元全自动影像测量仪、X射线荧光光谱仪等检测设备,确保产品合格

交付实力100套精密模具月产量,7天模具制造

交付实力100套精密模具月产量,7天模具制造15年高精模具研发经验,拥有15000m²生产基地,134台生产设备,月产100套精密模具,48h出手板,7天模具制造,24h内注塑打样,24h内量产出货。

品控保障通过ISO90001认证,T1合格率超90%

品控保障通过ISO90001认证,T1合格率超90% 严格执行ISO9001,通过IATF16949、ISO13485医疗认证,拥有德国三维扫描仪、瑞典三次元测量仪等进口检测设备,模具精度达±0.002mm,金蝶ERP系统管控生产流程,加工、测量、装配都在恒温车间,保证模具精度,T1合格率超90%。

技术团队20+年模具设计经验,20+项国家专利证书

技术团队20+年模具设计经验,20+项国家专利证书20年行业经验的专项设计团队,拥有PMP证书,市高层次人才证书,获得20+项国家专利证书,掌握EDM技术,VDI标准纹面、C轴加工、CNC加工等生产工艺,根据客户需求,提供OEM/ODM定制服务,24h出模具方案、48h出3D图,7天出样。

服务体系24小时在线服务,每周2次汇报实际进度

服务体系24小时在线服务,每周2次汇报实际进度售前:根据不同应用提供选型及DFM技术咨询;售中:通过MAS系统管控模具生产进度和质量,每周2次主动汇报实际加工进度;售后:在模具使用寿命内,免费维修,免费保养服务,免费提供易损件。快反机制:省内24h,省外72h到达现场

2025/07/04头条

2025/06/17头条

2023/09/20头条

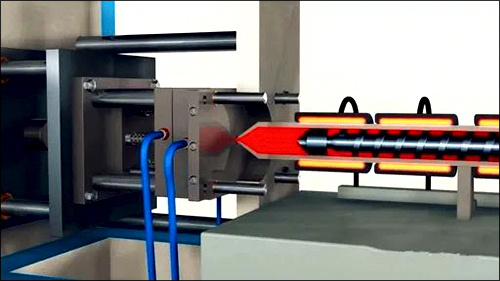

在美域同润的模具设计制造中,除了常规设计加工外,也会使用热流道,它可以大大提高效率,减少水口料,减小成型周期,在大规模塑胶产品的生产中,可以大大提高效率,增加稳定性,降...

美域同润,超过20 年的模具设计制造经验,在大...

塑胶产品的生产过程中,除了模具的设计制造至关重...

模具设计制造和注塑加工的最终目的,也是为了生产...

美域同润设计制造塑胶模具、压铸模具等,由于很多...

在模具设计制造中,有很多注意事项,美域同润提供...

在注塑成型过程中,很容易出现代价高昂的错误。注...

深圳市美域同润实业有限公司,成立于2008年,占地15000m²,是一家从事精密模具与注塑加工的国家高新技术企业,集模具设计、模具制造、注塑加工与产品装配于一体,为客户提供OEM/ODM定制化服务,产品广泛应用于医疗器械、电子电器、汽车配件、美容仪器、照明等领域。15年来,与全球各大企业合作,客...【了解更多】